Injection Molding

Our fastest injection machines can produce 144 preforms every 7.5 seconds, so we truly are a high speed preform manufacturer.

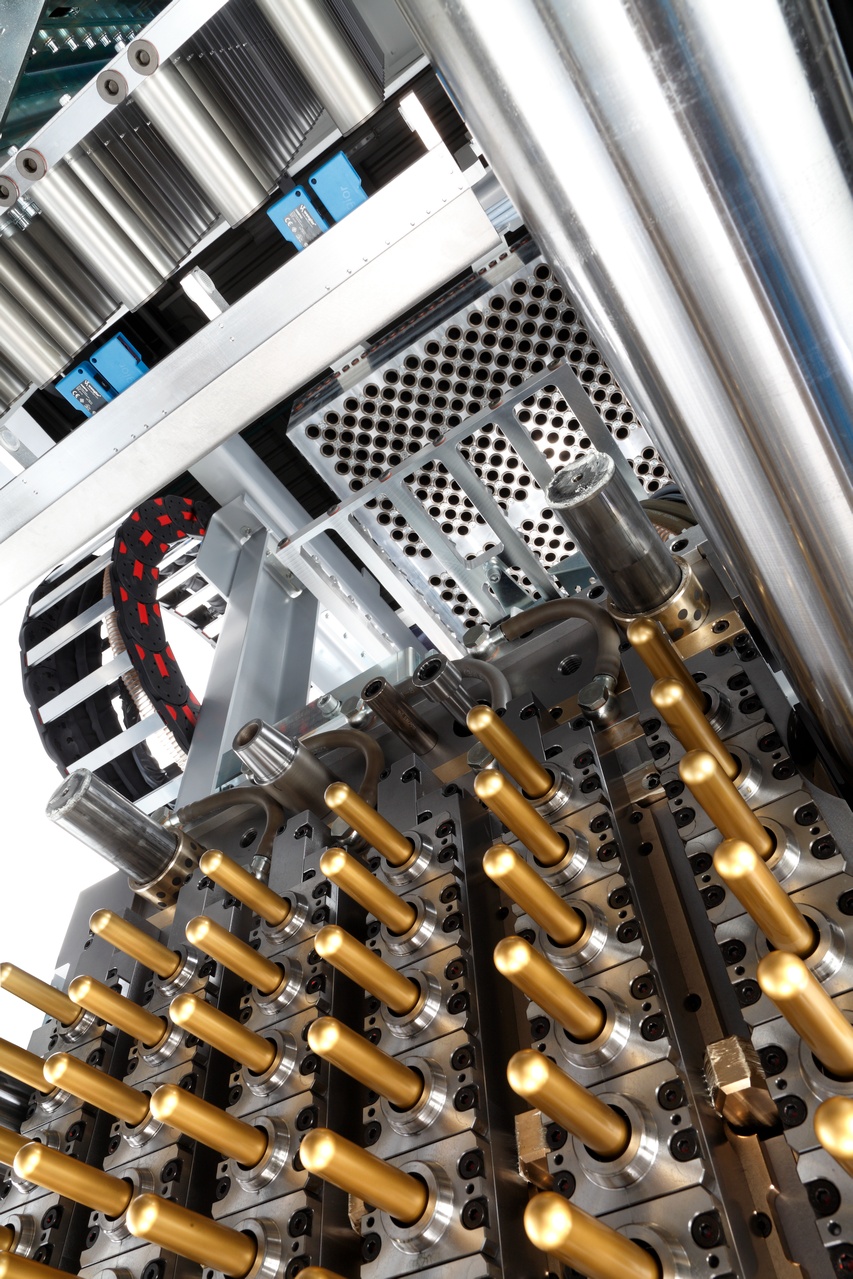

The first stage in the bottle making process is to produce a preform which looks like a test tube with a thread attached to it. Preforms are produced on injection molding machines which take incoming PET resin chips, melt them, and then inject them into a multi-cavity preform mold. The molten resin is injected at 550 degrees F. and then cooled down rapidly with chilled water. Preforms are removed from the mold via a robotic arm, cooled further, then conveyed into re-usable plastic storage bins.

WCC utilizes molds from North American and European suppliers which range in size from 96 to 192 cavities. Our fastest injection machines can produce 144 preforms every 7.5 seconds, so we truly are a high speed preform manufacturer. Our preforms range from 11.5g to 70g in weight, and they are used to blow predominantly carbonated soft drink, water, and sport drink bottles.

Our Equipment Suppliers

- Netstal

- Husky